Research in Action: Wireless monitoring of sewer pipes can crack savings down the line

May 2021, by Julio Heleno Gomes

With spring around the corner and the ground beginning to thaw, a device being developed by a Lakehead University researcher could be a new tool for the City of Thunder Bay to improve inspection of its network of underground sanitary sewer pipes.

Using a probe outfitted with sensors and a camera, this device could detect sewer defects and pipe damage, which would benefit the city’s wastewater system.

Using a probe outfitted with sensors and a camera, this device could detect sewer defects and pipe damage, which would benefit the city’s wastewater system.

“We hope the device is easy to use and will successfully detect infiltration above and below the sewer surface inside the collection pipe,” says Michelle Warywoda, Director of Environment, Infrastructure and Operations for the City of Thunder Bay.

“We hope that results from the sewer pipe inspections with the device will inform the City’s sanitary sewer system capital replacement and rehabilitation program.”

Dr. Amir Azimi is working on a project to detect faults along the city’s 515 kilometres of sanitary sewer pipes. During spring snow melt or severe rainfall, heavy moisture infiltrates the ground and if there’s a crack in the sewer additional water will flow into the collection system, mixing with sewage.

Conventional inspection and monitoring is done via closed circuit TV cameras, which is labour intensive and requires trained operators.

“That’s not feasible and is very expensive,” Azimi says of that method.

An associate professor in the department of Civil Engineering, Azimi’s research focus is hydraulics and environmental fluid mechanics.

In the case of sewer pipes, residential wastewater is typically at room temperature (in the 20 C range), whereas water from snowmelt is only about 5 C. The resulting temperature difference would indicate a flaw somewhere in the drainage pipe.

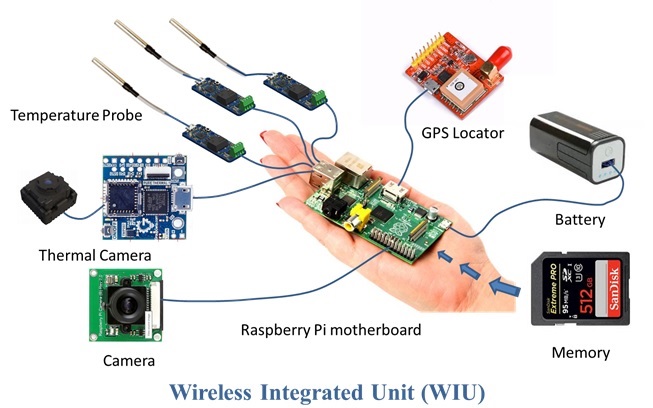

Azimi’s device consists of a temperature probe, thermal camera, GPS locator, battery and memory card. It would maneuver through the pipe and take temperature readings. It can record differences of as little as one degree Celsius.

“We drop it in a manhole, it flows with the sewage, we retrieve it downstream, grab the data and look at the temperature variations,” Azimi says of how the device will be utilized. “If the temperature is constant, it’s OK. But at one line it could be 18 degrees, 18 degrees and then it drops to 14 degrees and then goes back to 18. When the temperature goes down, you know something is going on in the pipe.

“This is not very difficult to measure and it’s very fast and cheap.”

By detecting defects in the sewer pipes, rehabilitation work can be targeted by sending closed-circuit TV cameras to a specific spot to verify there’s a problem. This will reduce the infiltration of groundwater into the sanitary sewer system, Warywoda explains.

Azimi has been working on this device with a team of students: graduate student Xunjia Liang and undergraduates Gurpreet Chaggar and Adam Talbot.

Along with grants from the Natural Sciences and Engineering Research Council of Canada, Azimi has also received support from the City. He has been working on a combination of sensors and five different prototypes. But the device is not yet ready to be used in the field.

“That was not the plan for the funding,” Azimi says. “Funding was for the proof of concept, to see if we could build the submarine device and to see if the sensors would work.”

Due to COVID-19 the next stage in the project development is currently on hold but will resume once the graduate student researchers are able to reconvene.

When things return to normal, Azimi hopes to run more tests, such as try to determine the rate of flow through a crack and the minimal difference in temperatures the probe could detect. The concept has other applications, such as measuring the salinity of lakes or the pH levels of industrial discharge.

The potential of wireless monitoring of sewer pipes is enough that Warywoda imagines it could become a part of the City’s regular sewer inspection program. The benefits are obvious: when you reduce the volume of groundwater entering the sewer, less wastewater goes to the Water Pollution Control Plant for treatment, saving on energy, chemical usage and equipment run time.

“That translates to a reduction in maintenance and operational costs,” Warywoda says.

The pipes, which are variously made of concrete, plastic, clay, steel, asbestos-cement and wood stave, are on average more than 50 years old and are susceptible to damage and deterioration.

“Tree roots can get into the cracks in pipes or between pipe joints,” Warywoda says. “Pipes can also become misaligned or crack from movement of soils around them.”

Research in Action highlights the work of Lakehead University in various fields of research.